1. What is Organic Fertilizer?

- Organic fertilizer inputs in agricultural fields in the present scenario has significant environmental benefits over the use of chemical fertilizers and the practic has gained much importance.

- Organic fertilizer differs from chemical fertilizer in that they feed your plants while building a healthy soil. They are considered the more environmentally friendly option. Soils with plenty of organic material remain loose and light, retain more moisture and nutrients, and foster growth of soil micro-organisms that promote healthier plants and root development.

2. Advantages of Organic Fertilizer?

Enhance the ability of land to resist cold and drought

- Continuous application will enrich the soil, then the soil will become more and more fertile, so the land is resistant to cold and drought and the fruit trees will have a good rest.

Improve soil and reduce salt damage

- Adjust the acidity and alkalinity, balance soil PH data, increase the permeability of soil, and promote the formation of granule structure.

Greatly improve the quality of agricultural products

- Sweeten and color the fruits, restore the original taste of vegetables;

- Increase the content chlorophyll of tea and reduce the residue of pesticides and chemical fertilizers;

- It contains EM bacteria, which can fix nitrogen, remove phosphorus, release potassium and increase chlorophyll content in plants, making the yield of crops increase significantly.

Increase the microbial content in the soil

- Inhibit the growth and reproduction of pathogenic fungi in soil, and improve the ability of crops to resist disease and continuous cropping.

- Promote seed growth and improve photosynthesis of crop

- Promote early germination and rooting of seeds and underground stems, and their developed root system.

- Improve the photosynthesis of crops, adjust the rational distribution of nutrition, promote the rapid expansion of fruits and eraly coloring, so the fruits will ripen 7-10 days early.

3. Where can derive of organic fertilizer?

Commercial Organic Fertilizers:

- Industrial waste: such as distiller’s grains, vinegar grains, cassava residues, sugar residues, furfural residues, etc.

- Municipal sludge: such as river sludge, sewer sludge, etc. Organic fertilizer raw material production and supply base classification: silkworm sand, mushroom residue, kelp residue, phosphocitric acid residue, cassava residue, protein mud, glucuronide residue, amino acid humic acid, oil residue, grass ash, shell powder, concurrently operating, peanut shell powder, etc.

Bio-Organic Fertilizer:

- Agricultural waste: such as straw, soybean meal, cotton meal, etc.

- Livestock and poultry manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

- Household garbage: such as kitchen garbage;

4. Organic Fertilizer Production Line

In order to meet the needs of the large-scale organic fertilizers, We Henan Tongda Heavy Industry Science and Technology Co., Ltd. professionally design and manufacture the organic fertilizer production line and relevant machines fitting for different organic materials, which has been the leader in the field in China.

| Annual Output of Small-Sized Organic Fertilizer Plant (300 Working Days) | |||||

| 10,000 tons/ year | 20,000 tons/ year | 30,000 tons/ year | |||

| 1.4 tons/ hour | 2.8 tons/ hour | 4.2 tons/ hour | |||

| Annual Output of Medium-Sized Organic Fertilizer Plant | |||||

| 50,000 tons/ year | 60,000 tons/ year | 70,000 tons/ year | 80,000 tons/ year | 90,000 tons/ year | 100,000 tons/ year |

| 6.9 tons/ hour | 8.3 tons/ hour | 9.7 tons/ hour | 11 tons/ hour | 12.5 tons/ hour | 13.8 tons/ hour |

| Annual Output of Large-Sized Organic Fertilizer Plant | |||||

| 150,000 tons/ year | 200,000 tons/ year | 250,000 tons/ year | 300,000 tons/ year | ||

| 20.8 tons/ hour | 27.7 tons/ hour | 34.7 tons/ hour | 41.6 tons/ hour | ||

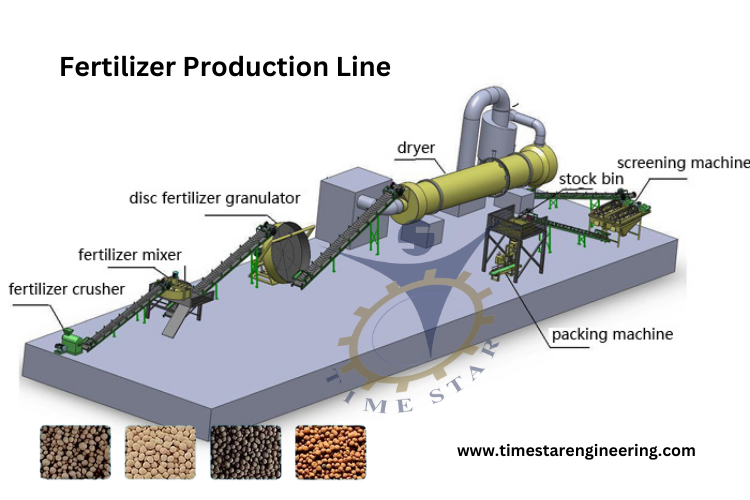

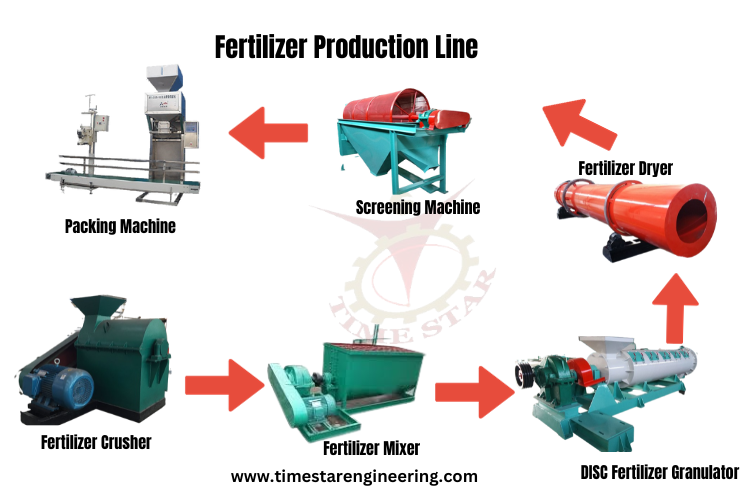

5. Working Process of Organic Fertilizer Production Line

- Fermentation Process:

- Fermentation is the basic process of production. Moisture, temperature and time need to be strictly controlled. A compost turner is an organic fertilizer machine used to accelerate the fermentation of microorganisms and improve the quality of compost.

- Crushing Process:

- Lump materials should be crushed after the fermentation process. It is difficult to make the matter into granules manually. In this way, it is necessary to use a fertilizer crusher. We recommend customers choose high moisture materials crusher machine, as it can crush semi-wet material with high crushing efficiency.

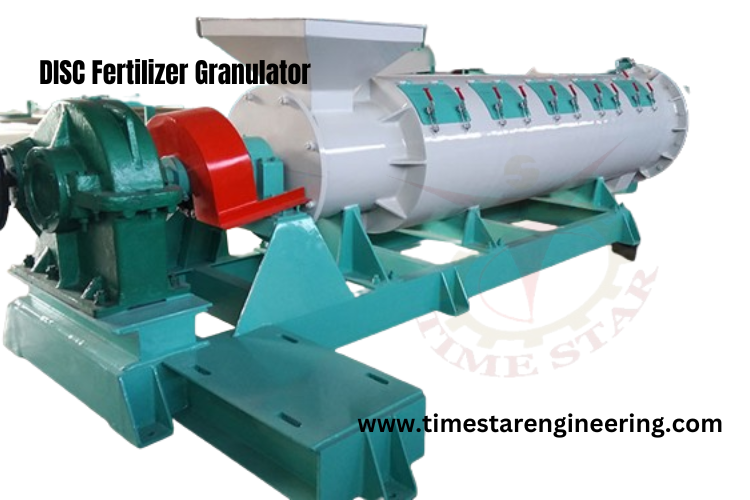

- Granulating Process:

- It is an important production process in the whole production line. According to different requirements, nutrients can be added. Spherical particles are processed, saving plenty of energy. Therefore, choosing the proper organic fertilizer machine is particularly essential. A new type organic fertilizer granulator is the most suitable machine.

- Drying Process:

- After granulating, the granules are in need of drying. The moisture of organic fertilizer is reduced to 10%-40%. Rotary drum dring machine is an equipment to reduce the moisture of the particles, which is feasible for organic fertilizer production.

- Cooling Process:

- In order to ensure quality, the particles should be cooling after drying with the help of rotary drum cooling machine.

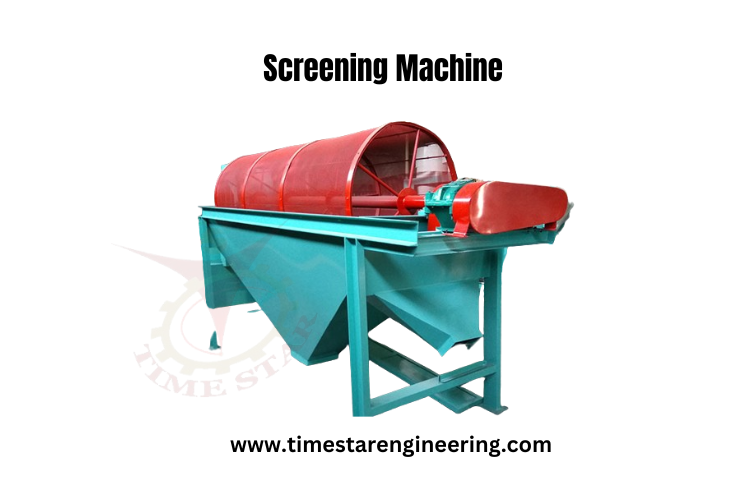

- Screening Process:

- There are unqualified organic fertilizers during production. It needs rotary drum fertilizer screening machine to separate the rejected goods from standard substance.

- Packing Process:

- Fertilizer packaging machine is used for packing processed fertilizers. We can use packing machine to pack and bag the particles.It can achieve pack products automatically and efficiently.

Reviews

There are no reviews yet.