At Time Star Engineering, we offer full automatic hard & soft biscuit production lines designed to meet the diverse needs of the biscuit manufacturing industry. Our advanced production systems provide a seamless and efficient solution for producing high-quality hard and soft biscuits, with an emphasis on consistency, precision, and high output.

Our fully automated production lines are engineered to handle the entire biscuit-making process, from dough mixing and shaping to baking, cooling, and packaging. Equipped with the latest technology, these lines offer optimal control over key parameters such as baking time, temperature, and biscuit texture, ensuring that each product meets the highest standards of quality.

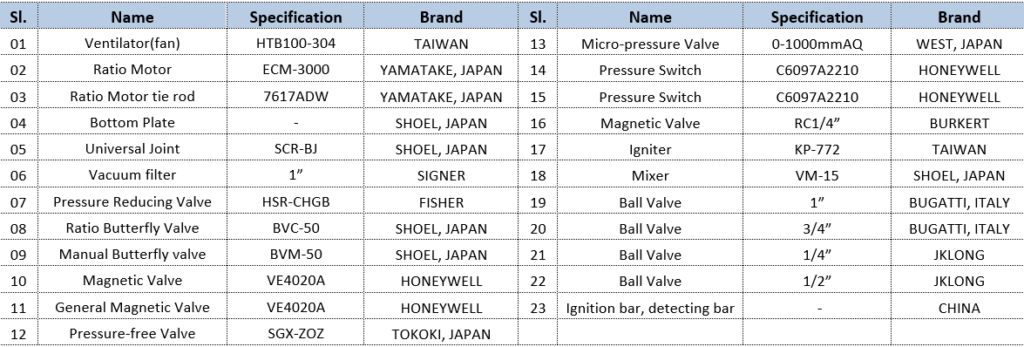

Baking oven

Our biscuit production line seamlessly integrates with a variety of advanced ovens, including hybrid ovens, hot-air circulation electric ovens, and hot-air circulation gas baking ovens. These ovens are equipped with individually adjustable temperature zones, each controlled by a precise PLC system, ensuring consistent and even baking for perfect biscuit texture and color.

The baking oven is designed for optimal performance and flexibility and is complemented by additional components such as the oven drive system, entry conveyor, exit conveyor, and a peeling machine. These features work together to ensure smooth operation, easy handling, and efficient transfer of biscuits throughout the baking process.

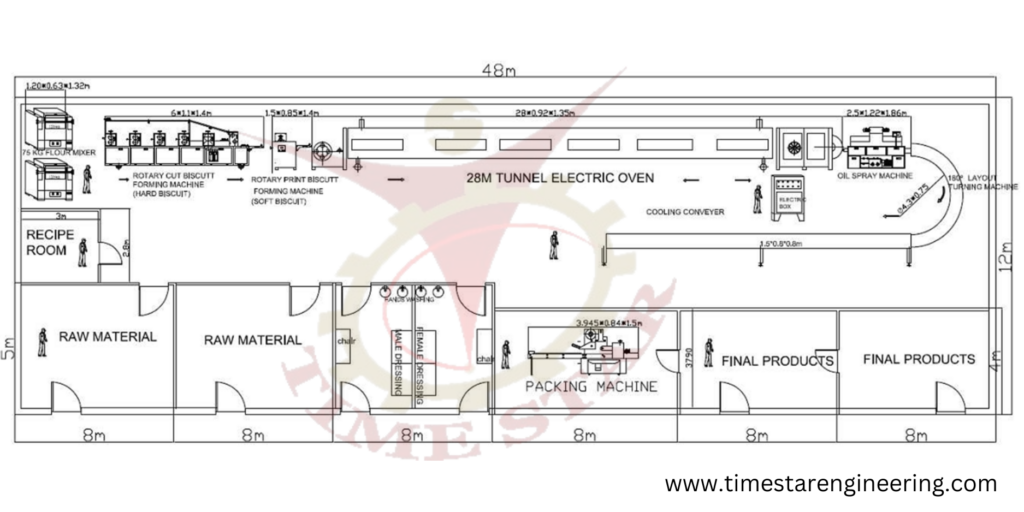

Layout

PROCESSING FLOW:

FLOUR MIXING >DOUGH SHEETING >MOULDING >BAKING >OIL SPRAYING >COOLING >PACKING

LAYOUT DESIGN:

We supply turnkey plant includes factory layout design, machine installation, working training and recipes supply.

Following is general layout for reference; exact layout will be designed as per client’s local area condition.

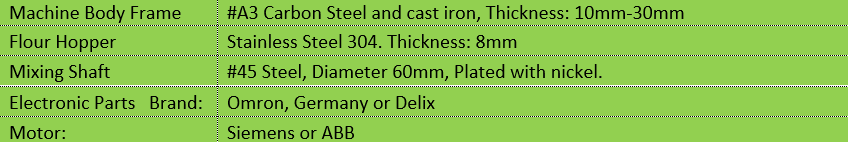

75kg flour mixer

FUNCTION: To mixing the flour with other ingredients

QH automatic biscuit production line, with original design, compact structure and high automatic, is developed on the base of absorbing Japanese technology. All working procedures that from dough feeding, sheeting, molding, waste recycling, baking to cooling can be completed automatically in one line. Hundreds of moulds and dozens of technology recipes make it possible to produce all kinds of popular biscuits, such as cream biscuit, layer biscuit, soda cracker, calcium biscuit, multi-vitamin biscuit, vegetable biscuit, etc.

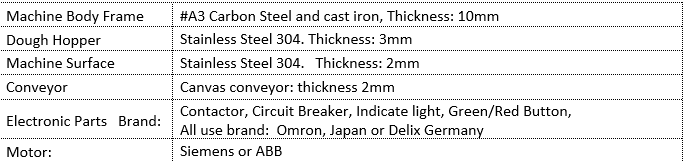

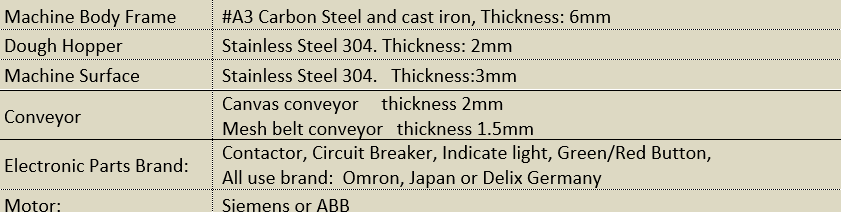

Material

- The equipment is made of bedplate, dough hopper, and beater; a reverse hopper driving and electronically controlled system, Etc.

- The food contact spare parts are all plated with nickel. Dough hopper inside surface is made of stainless steel.

- Beautiful and clean. To meet the standard of food.

Rotary-cut biscuit-forming machine (Hard)

Function: To sheet the dough and make shape for hard biscuit

Molding Machine is for hard biscuit, soda cracker, crispy /salt /thin biscuit. This Equipment has three gauge rollers to sheeting the dough.

Have three steps: Dough sheeting, hard biscuit molding, side material returning.

There are five conveying belts, two mesh belt are used for conveying the dough sheet, one mesh belt for the waste dough recycle, another two canvas belt are used for conveying the molded biscuit .

Basic parts : Adjust the hand wheel (3 sets) Printing Mold roller (with bearing); Canvas straining roller; Transmission chain of the printing roller; Motor speed adjustment gauge (some are placed inside). Canvas outlet adjustment roller; Transmission chain of the printing roller.

Rotary cut biscuit forming machine (Soft)

FUNCTION: To sheeting the dough and making shape for hard biscuit

Function:

Molding Machine for hard biscuit, soda cracker, crispy /salt /thin biscuit

This Equipment has three gauge rollers to sheeting the dough. Have three steps: Dough sheeting, hard biscuit molding, side material returning.

There are five conveying belts, two mesh belt are used for conveying the dough sheet, one mesh belt for the waste dough recycle, another two canvas belt are used for conveying the molded biscuit .

Basic parts : Adjust the hand wheel (3 sets) Printing Mold roller (with bearing); Canvas straining roller; Transmission chain of the printing roller; Motor speed adjustment gauge (some are placed inside). Canvas outlet adjustment roller; Transmission chain of the printing roller.