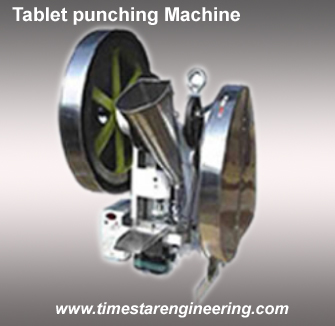

Overview

Single Punch Tablet Press Machine LSTP-A10 comes with 60 KN Maximum pressure and offers 25 mm maximum diameter. Features a small desktop type press for motive and continual sheeting. It can also be hand-operated. Only one pair of punching die can be erected on this press. Both filling depth of material and thickness of tablet are adjustable. Designed with high precision of filling, low noise, low consumption, of material, and it works smoothly. The maximum consumption of lab material is just 200 g. Tablets of different granular materials are pressed under pressure for use in research and quality preparations across pharmaceutical, food, chemical industry, cosmetic industry etc.

Features:

Designed with single punch structure is rational and small

Offers high amount of pressure to reduce weight variations between tablets while

maintaining a low noise level at the same time

Adopts flexible, lightweight tablet press that is utilized for compacting granulated and powdered materials into tablets

It is desktop type press for motive and control sheeting

Minimum consumption of lab material is 200 g

Adjustable thickness of the tablet

Easy to use and maintain

It is used for development of tablets and small batch production

Reviews

There are no reviews yet.